Why Metal Tube Building Kits Are Worth Your Attention

Metal tube building kits are pre-engineered steel structures using a hollow square tube frame, designed for DIY assembly. They are an affordable entry point into steel construction, making them popular for garages, workshops, and storage sheds under 2,000 sq ft.

These kits ship with components that often snap together, allowing a small crew to erect a basic structure in a few days with common tools. The cost for a kit typically ranges from $15-25 per square foot, with a lifespan of 10-20 years. However, their DIY-friendly design comes with trade-offs. The hollow tubing is lightweight but has structural limitations, making these kits unsuitable for harsh climates, heavy snow loads, or large clear spans. For more demanding conditions, cold-formed or solid I-beam steel is a better alternative.

Quality can vary significantly. Some kits use thinner, imported steel, while others feature engineered American steel with superior rust protection. With nearly two decades in the construction industry, my experience has shown that understanding the balance between cost, durability, and application is key to choosing the right building.

Understanding the Pros and Cons of Metal Tube Building Kits

Metal tube building kits are popular for good reason, but they aren't a one-size-fits-all solution. Their design, which uses hollow square steel tubing for the frame, creates a distinct set of advantages and limitations that you must understand before committing.

Primary Advantages of Tube Steel

Here's where metal tube building kits excel, making them a top choice for many homeowners.

- Cost-Effectiveness: The hollow tubing uses less material, which lowers manufacturing and shipping costs. This makes tube kits an accessible entry point into steel construction for those on a budget.

- Ease of Assembly: Many kits feature clever Slip-Fit connections that allow pieces to snap together without welding or specialized skills. The process is straightforward and satisfying for DIY enthusiasts.

- Lightweight Components: Because the components are lightweight, you won't need to rent a crane or forklift. Most parts can be handled by two people, keeping the project simple and affordable.

- Faster Construction: For structures under 2,000 square feet, you can go from a bare foundation to a usable building in just a few days. This speed is a major benefit if you're on a tight schedule.

- Ideal for Smaller Structures: These kits are perfectly suited for backyard workshops, storage sheds, and carports in temperate climates, providing functional space without a massive investment.

Potential Disadvantages and Risks

It's equally important to be aware of the limitations of tube steel construction.

- Structural Limitations: The hollow tubing that makes assembly easy is also the building's primary weakness. Compared to solid steel I-beams, thin-walled tubing cannot handle the same loads and can bend or warp under extreme pressure from wind, snow, or seismic events.

- Climate Considerations: If you live in an area with harsh winters, frequent hurricanes, or seismic activity, a tube steel kit may not be the safest choice. These structures have failed under heavy snow, high winds, and seismic stress in various parts of the country.

- Quality Control: Many kits are mass-produced overseas, which can lead to inconsistent quality. Some imported kits use thinner steel, have poor welds, or lack proper engineering certification, which can cause problems with local building permits.

- Load-Bearing Capacity: These structures are not designed to support heavy internal loads. Installing a car lift or hanging heavy equipment from the frame is typically not possible.

- Lifespan: A tube steel building has a typical lifespan of 10-20 years, significantly shorter than the 50+ years expected from a traditional steel building.

- Difficult to Expand: Modifying or expanding a tube steel building is challenging, as the original structure is not designed for additions. This lack of flexibility can be a problem if your needs change.

The bottom line is that metal tube building kits are excellent for smaller structures in moderate climates where budget is a key factor. For larger buildings, harsh weather, or heavy-duty use, more robust options are necessary. At Cascading Falls Inc., we help you match the building type to your specific needs. Check out our services to see how we can guide you.

Tube Steel vs. Other Metal Building Approaches: A Head-to-Head Comparison

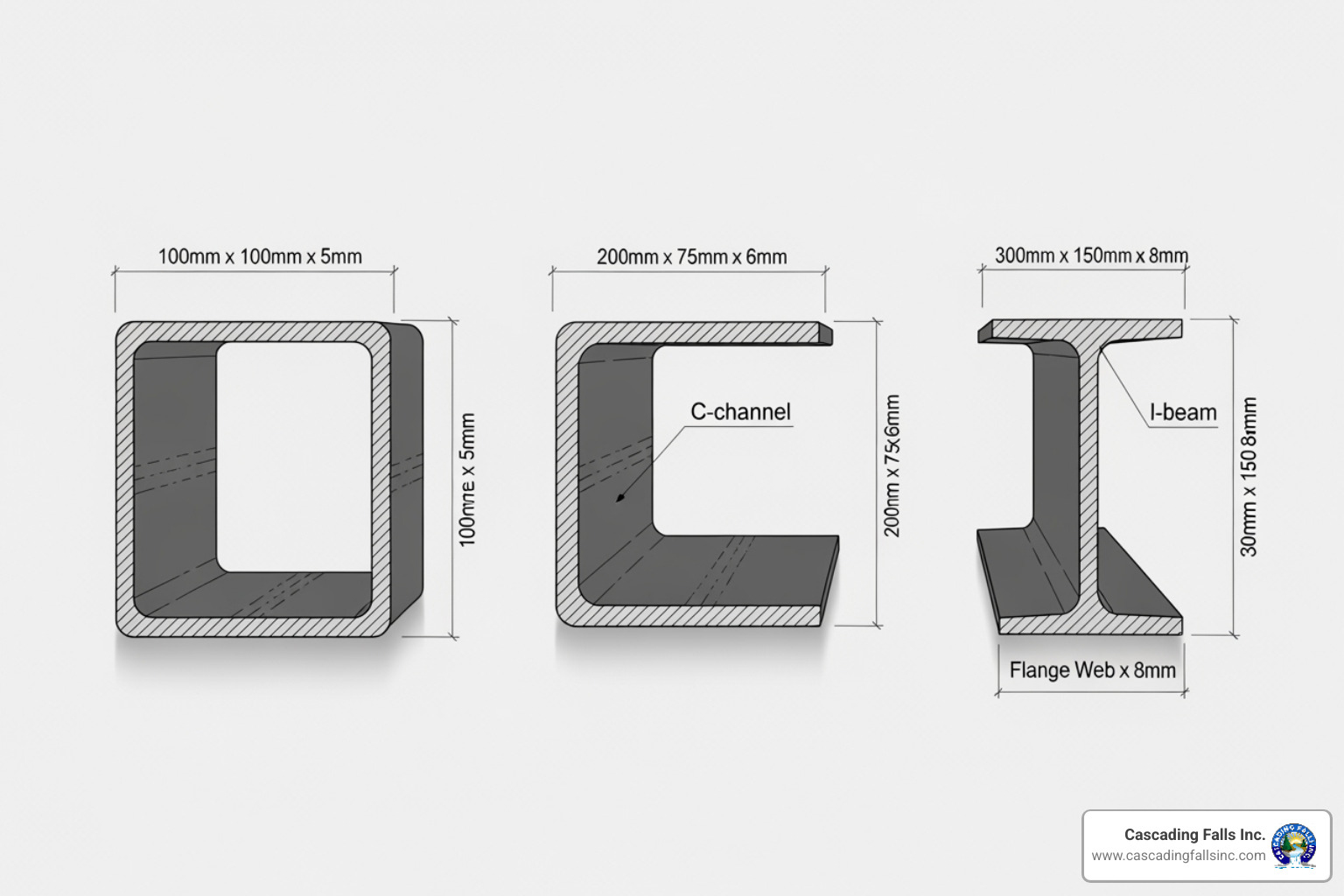

When shopping for a steel building, you’ll encounter terms like metal tube building kits, "cold-formed steel" , and "red iron I-beams." Each system is designed for a different purpose, much like how a compact car, a pickup truck, and a semi-trailer are all vehicles but serve very different functions.

How Tube Kits Compare to Other Steel Building Types

Metal tube building kits are the affordable, easy-to-handle option for everyday needs. But for projects requiring more strength, other systems are superior.

Heavier-duty steel construction (Red Iron I-Beams) uses solid steel I-beams , offering unparalleled strength and durability. These structures can create massive clear spans (up to 300 feet) and easily support heavy equipment like overhead cranes. They are built to withstand extreme weather and last 50+ years, but they come with a higher price tag and require professional erection with heavy equipment.

Cold-formed steel framing uses C-channel or Z-channel profiles made from bent steel sheets. This method provides more structural integrity than hollow tubes (see hollow structural section ) but is lighter than solid I-beams. It's a versatile middle ground for mid-sized garages, workshops, and commercial buildings with spans up to 60-80 feet. These buildings also have a 50+ year lifespan and may allow for some DIY involvement, though more specialized tools are often needed.

The key differences come down to strength, durability, cost, and application. Tube steel is the lightest and most affordable but weakest, while red iron is the strongest and most expensive.

Here's a quick comparison:

| Metric | Tube Steel Building Kits | Cold-Formed Steel Buildings | Heavier-Duty (Red Iron) Steel Buildings |

|---|---|---|---|

| Strength | Low (thin-walled, hollow) | Medium (C-channel/Z-channel) | High (solid I-beams) |

| Cost | Lowest | Medium | Highest |

| Lifespan | 10-15 years | 50+ years | 50+ years |

| DIY-Friendliness | Very High (snap-together, no heavy equipment) | Medium (some DIY possible, may need specialized tools) | Low (professional erection, heavy equipment required) |

| Typical Span | Small (up to ~40 ft) | Medium (up to ~60-80 ft) | Large (up to 300+ ft clear span) |

Metal tube building kits are excellent for their intended purpose: providing affordable, easy-to-assemble structures for smaller applications in moderate climates. However, for projects demanding more strength, larger spans, or a multi-decade lifespan, cold-formed or red iron construction is the smarter investment. At Cascading Falls Inc. , we help property owners understand these differences to choose the right building for their needs and budget.

Your Pre-Purchase Checklist: Choosing the Right Kit

Picking the right metal tube building kit requires careful consideration beyond the price tag. You need a structure that meets your needs, complies with local regulations, and offers long-term value. At Cascading Falls Inc., serving Roseville, Sacramento, and throughout California, we know what separates a great choice from a costly mistake.

Materials, Manufacturing, and Quality Control

The quality of the steel and manufacturing directly impacts your building's durability. Ask potential suppliers about the following:

- Steel Origin and Gauge: Reputable manufacturers often use American steel, which adheres to stricter quality standards. In contrast, some overseas kits may use thinner steel (a higher gauge number) that is less durable. Always ask for specifics on steel thickness.

- Rust Protection: Bare steel will corrode. Look for galvanized coatings to create a protective barrier. Premium triple-coat protection systems can significantly extend the life of your building.

- Weld Quality: If your kit has welded components, poor welds can create weak points. Reputable manufacturers will provide details on their quality assurance processes.

- Manufacturer Reputation: Research the manufacturer by checking reviews and asking for references. A company with a solid track record will be transparent about its materials and engineering.

Engineering for Wind, Snow, and Seismic Loads

Proper engineering is essential for safety and legal compliance, especially in California, which has seismic risks, variable winds, and snow in higher elevations.

- Certified, Site-Specific Engineering: Insist on stamped engineering plans that are specific to your exact location. Generic plans may not meet local building codes for wind, snow, and seismic loads, leading to permit denials or an unsafe structure.

- Local Building Codes: Requirements for wind resistance, snow load capacity (measured in pounds per square foot, or PSF), and seismic design vary by county and city. A good supplier provides engineering that accounts for your area's worst-case-scenario conditions.

- Seismic Considerations: Given the structural limitations of hollow tubing, it is critical that your kit's engineering specifically addresses the seismic requirements for your zone in California.

For help navigating these requirements and ensuring your project meets all local standards, check out more info about our building services.

Customization and Expansion Options

Most manufacturers offer customization to help your kit fit your vision.

- Size and Roof Style: Widths typically range from 10 to 40 feet. Beyond the basic gable roof, some companies offer mansard or gambrel styles for aesthetic appeal or extra headroom.

- Doors, Windows, and Colors: Plan the placement of roll-up and personnel doors, as well as windows for natural light. Most kits come with a range of panel and trim colors to personalize the look.

- Interior Finishing: If you plan to use non-standard materials like wood siding or stucco, confirm the framing system can support them.

Be aware that most tube steel buildings are difficult to expand. The structural limitations of hollow tubing make adding on problematic. While some manufacturers may mention 'expandable end walls', this feature is more reliably found in robust cold-formed or red iron buildings. If you anticipate needing more space, it's better to build larger initially or choose a different building type.

From Foundation to Finish: The Erection Process

Once you've chosen your metal tube building kit, the next step is construction. These kits are designed for simplicity, but understanding the entire process from foundation to finish is key to a successful project.

Is DIY Installation a Realistic Option?

Yes, for many people, DIY installation is a realistic and major selling point of metal tube building kits. Manufacturers design them to be accessible, with snap-together or slip-fit assembly systems that don't require welding or heavy equipment. For smaller structures, two people can often erect the frame over a weekend.

However, "DIY-friendly" still requires basic construction skills and tools like wrenches, drills, and levels. It is absolutely essential to follow the manufacturer's instructions precisely. Do not improvise or skip steps, as the instructions are engineered for safety and structural integrity. Cutting corners can compromise the building's ability to withstand environmental stresses.

The Importance of a Proper Foundation

While you can assemble the kit yourself, the foundation is a job best left to professionals. A building is only as strong as its foundation. An improperly prepared base will lead to structural problems.

Your site must be level, clear, and compacted before construction begins. For metal tube building kits, a concrete slab or pier foundation is typically used, depending on building size and local codes. A poorly poured foundation can cause issues like misaligned panels and doors, and structural stress that shortens the building's lifespan.

Hiring a professional concrete contractor is a worthwhile investment. At Cascading Falls Inc., we've seen many projects falter due to foundation issues. That's why we offer expert Concrete Services in Roseville, Sacramento, and surrounding areas to ensure your building has the solid, code-compliant base it needs.

Cost Implications of Metal Tube Building Kits

Understanding the full cost is crucial. The kit price, typically $15 to $25 per square foot, is only the starting point.

- Foundation: Budget an additional $5 to $10 per square foot, or more for challenging sites.

- Labor: If you don't DIY the installation, get clear quotes for professional labor.

- Finishing: Insulation, electrical, plumbing, and interior walls will add to the cost, starting around $10 per square foot and increasing with complexity.

Also, consider the long-term value. A tube steel building's 10-15 year lifespan is shorter than that of more robust structures. Investing more upfront in a cold-formed or red iron building, which can last 50+ years, may offer better value over the long term.

We encourage clients to think beyond the initial price. Your long-term plans, intended use, and local weather should all factor into your decision. For more guidance on planning your project, check out More info about our building services.

Frequently Asked Questions about Metal Tube Kits

Here are answers to the most common questions we hear from clients in Roseville, Sacramento, and across California about metal tube building kits.

What is the typical lifespan and maintenance for a metal tube building?

A metal tube building kit typically lasts between 10 and 20 years, with 10-15 years being a conservative estimate. This is a trade-off for the lower upfront cost compared to cold-formed or red iron buildings, which can last 50 years or more.

Fortunately, metal buildings are low maintenance. They are resistant to rot, mold, and pests. You won't need to paint or stain the structure. Maintenance involves a semi-annual checkup to ensure fasteners are tight and seals around doors and windows are intact. An occasional wash with mild soap and water will protect the exterior panel finish.

Are metal tube building kits environmentally friendly?

Yes, steel is a sustainable building material. Most metal tube building kits are made with a high percentage of recycled content, and the steel is 100% recyclable at the end of the building's life. The pre-engineered nature of kits also creates significantly less construction waste (around 2%) compared to traditional wood construction (up to 20%). Additionally, a properly insulated metal building with a cool metal roof can be very energy-efficient, potentially reducing cooling costs in hot climates like California's.

What kind of warranties are typically offered?

Warranties provide a safety net for your investment. Most reputable manufacturers offer a 20-year warranty on the frame against manufacturing defects. The exterior panels often have a separate 20 to 40-year warranty against paint fading, chalking, or peeling.

It is critical to read the warranty fine print before you buy. Understand exactly what is covered and what conditions might void the warranty, such as improper installation or unauthorized modifications. Also, clarify who is responsible for handling warranty claims, especially if the kit is imported.

For more guidance on selecting the right building, visit our Blog for tips and insights. When you're ready to start your project, explore Our Services to see how we can help.

Conclusion

When it comes to metal tube building kits, they are an attractive option for smaller projects like backyard workshops, sheds, or carports in mild climates. The low cost of $15-25 per square foot and DIY-friendly assembly offer significant savings.

However, it's crucial to remember their limitations. The hollow tube frame that makes them easy to build also limits their strength. For areas with heavy snow, high winds, or seismic activity—common in many parts of California—a tube steel structure is a risk. A building that fails is not just a financial loss but a safety hazard.

With a 10-15 year lifespan, you might find yourself replacing the structure while a more robust cold-formed or red iron building is still in its prime after 50 years. If your project demands durability, longevity, or the ability to span large distances, investing more upfront in a stronger steel building is the wiser choice.

Don't let a low price be your only guide. Consider your local building codes, climate, and intended use. Always insist on certified, site-specific engineering plans.

At Cascading Falls Inc., we guide property owners in Roseville, Sacramento, and throughout California to make these critical decisions. We stand by our "Whatever It Takes..." commitment to quality, whether you need expert advice or a professional concrete foundation.

For more building tips, visit our Blog. Ready to start your project? Explore Our Services to see how we can bring your vision to life.