Why Industrial Steel Buildings Are the Smart Choice for Your Next Project

Industrial steel buildings are pre-engineered structures made primarily from steel components, designed for commercial, manufacturing, agricultural, and community applications. Here's what you need to know:

What Makes Industrial Steel Buildings Stand Out:

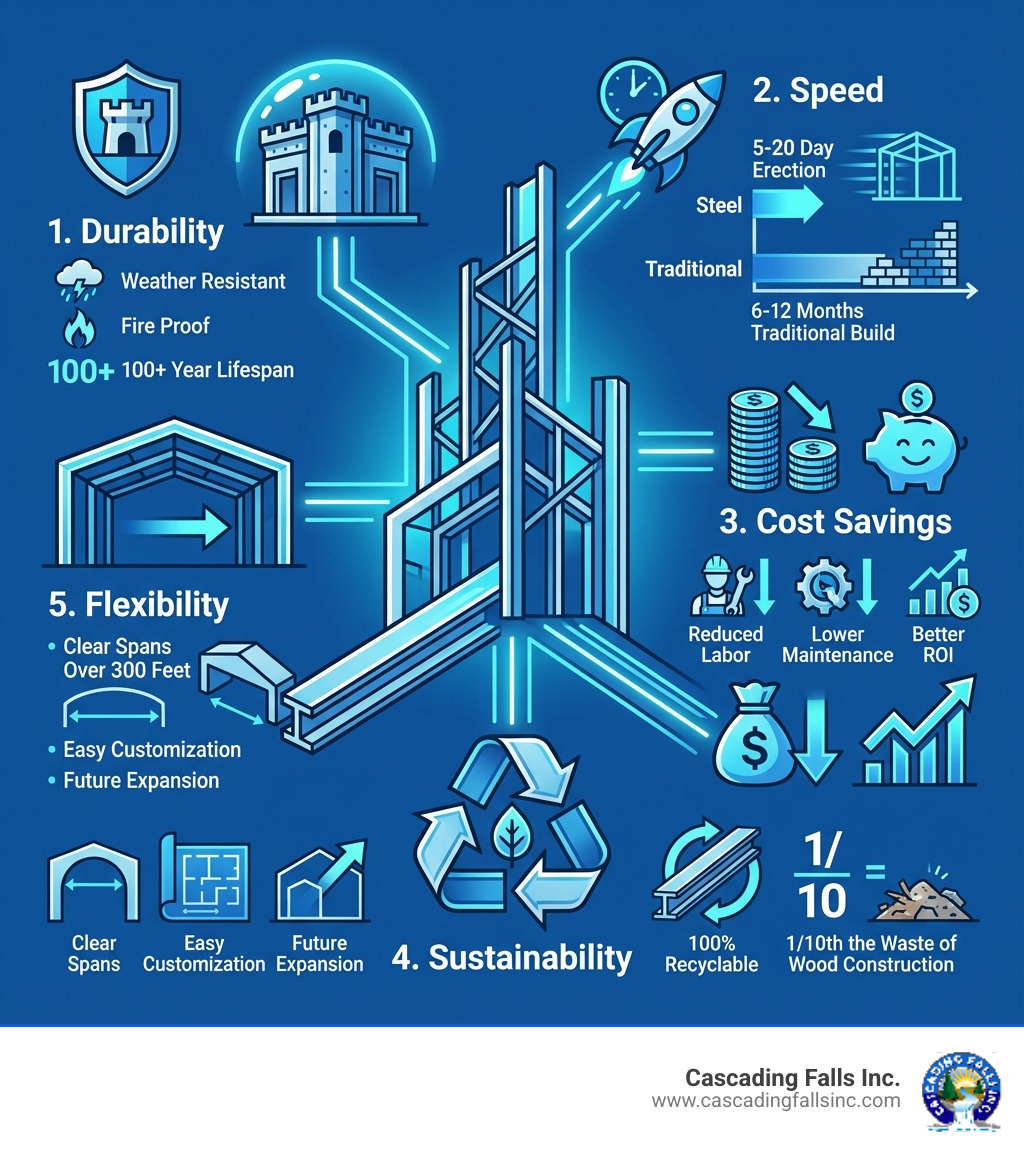

- Strength & Durability- Engineered to withstand harsh weather, resist fire, and last 100+ years

- Speed of Construction- Prefabricated components reduce build time from months to just 5-20 working days

- Cost Efficiency- Lower labor costs, minimal maintenance, and excellent long-term ROI

- Design Flexibility- Clear-span designs up to 300+ feet, easily customized for cranes, mezzanines, and specialized equipment

- Sustainability- Nearly 100% recyclable steel with one-tenth the waste of traditional construction

Common Applications:

- Manufacturing facilities and warehouses

- Agricultural buildings and equipment storage

- Aviation hangars and commercial workshops

- Distribution centers and logistics hubs

If you're exploring building types for your property, steel offers best versatility. Whether you need a 50x100 warehouse, a specialized manufacturing facility with overhead cranes, or an agricultural storage building, pre-engineered steel adapts to virtually any requirement while delivering faster timelines and lower costs than traditional construction methods.

I'm David Shelly, and with nearly two decades of experience in construction design, project management, and installation since 2005, I've seen how industrial steel buildings transform operations for property owners. My background in both residential and commercial projects has given me deep insight into what makes these structures such reliable, high-quality solutions.

Why Choose Steel? The Best Advantages Over Traditional Construction

When we talk about constructing new facilities, the choice of material is paramount. We believe that steel stands head and shoulders above other options, especially for industrial applications. It's not just about erecting a structure; it's about building a robust, efficient, and future-proof asset for your business.

Durability and Resilience Against the Elements

One of the most compelling reasons to choose steel is its inherent strength and resilience. Steel buildings are engineered to withstand harsh weather conditions, from heavy rains to strong winds, providing best long-term protection for your business. Unlike wood, steel is impervious to pests like termites and won't rot, warp, or crack over time. This makes it an excellent option for safeguarding your business, protecting assets, and ensuring the safety of your people.

Steel's robust nature also offers superior fire resistance compared to traditional wood structures, adding an extra layer of security for your valuable assets. We're talking about buildings designed to last, with many steel structures exceeding a 100-year lifespan when properly built and maintained. This incredible longevity means your investment continues to pay dividends for generations.

Cost-Effectiveness and Long-Term ROI

Investing in an industrial steel building isn't just a short-term expense; it's a strategic move for long-term financial health. The cost-effectiveness begins with the construction process itself. Prefabricated steel components streamline assembly, significantly reducing build times and minimizing disruptions to your operations. This translates directly into reduced labor costs and faster occupancy. While traditional construction methods can take anywhere from six to twelve months, a prefabricated steel building can be erected in as little as 5 to 20 working days, depending on its size. That's a huge difference for your project timeline and bottom line!

Beyond construction, steel buildings minimize maintenance efforts and expenses for years to come. Their durability means fewer repairs and less upkeep compared to other materials. Furthermore, steel buildings offer excellent opportunities for energy efficiency. With options for high R-value insulation, you can conserve energy, reduce day-to-day operating costs, and enjoy lasting value year after year. This combination of lower upfront and ongoing costs ensures a strong return on investment (ROI).

A Sustainable and Eco-Friendly Choice

Environmental responsibility is more important than ever. Steel is one of the most sustainable building materials available, offering an eco-friendly solution that reduces environmental impact and conserves natural resources. The steel used in our buildings is nearly 100% recyclable. This means that at the end of its incredibly long service life, the steel can be recycled without losing its inherent properties, avoiding landfills and reducing reliance on virgin materials.

Choosing steel also drastically reduces construction waste. An environmentally friendly material, steel creates one-tenth of the waste compared to using wood as a building material. This commitment to sustainability not only benefits the planet but also aligns with corporate responsibility goals, allowing you to build with the knowledge that you are utilizing one of the world's most environmentally-friendly building materials.

Designing Your Industrial Steel Building: Key Considerations

The beauty of industrial steel buildings lies not just in their strength, but in their incredible adaptability. When we design your facility, we're not just thinking about four walls and a roof; we're crafting a custom solution that meets your exact operational needs, both today and tomorrow.

Essential Structural Design for Industrial Steel Buildings

A cornerstone of steel building design is the clear-span capability. This means we can create vast, unobstructed interior spaces, free from interior columns, which is absolutely critical for many industrial applications. Imagine a manufacturing floor or a warehouse where you have complete freedom to arrange machinery, shelving, or equipment without structural interference. Our clear-span designs can extend in excess of 300 feet, providing unparalleled flexibility for your layout.

Beyond open space, structural design focuses on load-bearing capacity. Whether you need to support heavy machinery, extensive shelving, or specialized equipment, our engineers calculate and design the framework to safely accommodate these loads. This includes robust primary framing (often I-beams) and secondary framing (purlins, girts, wind bracing) that distribute loads effectively.

Most metal buildings require a concrete foundation, usually accompanied by slabs on grade, to anchor the structure securely and provide a stable base. We ensure that our designs meet or exceed all local and national building codes, providing engineer-certified stamped drawings as part of your building package. We adhere to the standard specifications of industry-recognized organizations like AISC (American Institute of Steel Construction), ensuring the highest quality and safety. You can find more information on design standards from AISC.

Customizing for Your Specific Operations

No two industrial operations are exactly alike, and your building shouldn't be either. Steel allows for endless design flexibility, enabling us to create custom spaces for your specific business needs. A key advantage for many industrial clients is the ability to integrate overhead cranes or other specialized equipment directly into the building's structure. We can design reinforced columns and runway beams to support the specified crane capacity, ensuring seamless workflow and operational efficiency.

We can also incorporate mezzanines for additional office space or storage, custom door and window placements to optimize natural light and access, and flexible interior layouts that can be easily reconfigured as your business evolves. From height and clearance requirements to dock spacing and workflow considerations, our team works closely with you to ensure your industrial steel building perfectly aligns with your operational requirements.

Planning for Future Growth and Expansion

One of the smartest aspects of choosing a steel building is its inherent adaptability for future expansion or modification. Businesses rarely stay static, and your facility should be able to grow with you. With pre-engineered steel buildings, additions and alterations are easily done. Whether you need to add new bays, extend existing sections, or reconfigure interior spaces, the modular nature of steel construction makes these changes far simpler and more cost-effective than with traditional buildings. This future-proofing capability ensures your initial investment remains valuable and relevant for decades to come.

From Blueprint to Build: The Pre-Engineered Process Explained

The journey from concept to a fully functional industrial steel building is remarkably efficient, thanks to the pre-engineered process. This method takes much of the guesswork and on-site complexity out of construction, delivering a high-quality structure with impressive speed.

The Streamlined Pre-Engineered Advantage

The magic of pre-engineered steel buildings begins off-site. Components are precisely designed, engineered, and fabricated in a controlled factory environment. This manufacturing process ensures every piece is cut, drilled, and welded to exact specifications, ready for assembly. When these precision-cut components arrive at your site, they fit together seamlessly, much like a giant construction kit.

This off-site preparation drastically reduces the amount of on-site labor required and speeds up the erection process. The result is a faster construction timeline, minimizing disruptions to your operations and allowing for quicker occupancy. This streamlined approach also ensures consistent quality, as each component is manufactured under strict quality control standards before it even reaches your property.

What's Included in a Building Package?

When you invest in an industrial steel building package, you're getting a comprehensive solution designed for efficient assembly and long-term performance. While specific inclusions can vary based on your project, a typical package will feature:

- Primary Framing: The main load-carrying members, often I-beams, designed to support the building's overall structure and specified loads.

- Secondary Framing: Structural members that distribute loads to the primary framing, including purlins (for the roof), girts (for the walls), and wind bracing. These are typically cold-formed light gauge sections.

- Wall and Roof Panels: High-quality steel sheeting, often 26-29 gauge, providing the exterior shell. Our standard roof panels, for example, might be 29-gauge steel with a durable finish, continuous from ridge to eave up to 27 feet, and designed with specific rib profiles for strength and weather-tightness.

- Fasteners: All necessary self-drilling fasteners for securing the roof and wall covering systems, as well as field connections for light gauge members.

- Sealants & Closures: Closed-cell polyethylene closures die-cut to panel profiles and sealants to ensure weather-tightness.

- Trim Package: Necessary trim for a finished appearance.

- Engineer-Stamped Drawings: Professional, certified drawings for anchor bolts, erection, and permits (upon request), ensuring compliance with local building codes.

While we provide detailed foundation reactions, the foundation design itself is typically the responsibility of the client's local engineer, and anchor bolts are usually sourced locally to meet specific project requirements and ASTM standards.

Understanding the Project Timeline

The efficiency of pre-engineered steel buildings truly shines when we look at project timelines. Here's a general comparison:

| Phase | Pre-Engineered Steel Building | Traditional Construction |

|---|---|---|

| Design & Engineering | Swift, standardized processes | Longer, custom design |

| Manufacturing | Off-site, concurrent with site prep | On-site, sequential |

| Site Prep & Foundation | Standard for both, but critical | Standard for both |

| Erection Phase | 5 to 20 working days(depending on size) | 6 to 12 months(full build) |

As you can see, the erection of a prefabricated steel building can be accomplished in a fraction of the time compared to traditional methods. This rapid assembly means you can get your business up and running, or expand your existing operations, much faster, leading to quicker returns on your investment.

Applications and Industries: Who Uses Industrial Steel Buildings?

The versatility of industrial steel buildings is truly remarkable. They are not one-size-fits-all, but rather a highly adaptable solution that serves a vast array of industries and applications, from the busy heart of manufacturing to the quiet efficiency of agricultural storage.

Manufacturing, Warehousing, and Logistics

These are perhaps the most common applications for industrial steel buildings, and for good reason. Manufacturing facilities, distribution centers, storage facilities, and logistics hubs all benefit immensely from the inherent advantages of steel. The clear-span design is a game-changer, providing wide-open spaces perfect for efficient workflow, accommodating large machinery, forklifts, and extensive shelving systems.

Whether it's light engineering operations, food processing plants, or even specialized facilities like biodiesel production or candle making, steel buildings offer the structural integrity and flexibility required. The 80x100 metal building package, for instance, is a popular option for industrial operations requiring a high degree of customization for these types of businesses.

Commercial, Agricultural, and Community Use

Beyond heavy industry, industrial steel buildings are incredibly versatile for a range of other sectors.

- Commercial: We design steel buildings for commercial use, including workshops and auto repair shops. Their durability and ease of customization make them ideal for these demanding environments.

- Agricultural: From protecting precious livestock to storing costly equipment, steel barns and farm buildings are a reliable choice. They offer a much better option than traditional pole barns or wooden buildings, providing robust protection against the elements and pests for farms of all sizes. This includes equipment storage, riding arenas, and other agricultural necessities.

- Community: Steel buildings are also widely used for public and institutional facilities. Community centers, fire stations, and other public works buildings benefit from their cost-effectiveness, longevity, and low maintenance.

Specialized and Heavy-Duty Applications

For projects with unique and demanding requirements, steel buildings truly shine.

- Aviation Hangars: With the ability to achieve clear spans in excess of 300 feet, steel buildings are the go-to choice for aviation hangars, protecting multi-million dollar aircraft and providing ample space for maintenance.

- Crane Buildings: As discussed, steel structures can be specifically engineered to integrate and support overhead cranes, essential for operations that involve lifting and moving heavy materials.

- Mining Infrastructure: In remote and harsh environments, steel buildings provide durable and reliable solutions for equipment storage, processing facilities, lodging, and office spaces.

- Waste Transfer Stations & Data Centers: For facilities requiring maximum security, specific environmental controls, or robust structural support for heavy loads and specialized equipment, steel offers a superior solution.

Sourcing and Ownership: What to Know Before You Buy

Choosing an industrial steel building is a significant investment, and ensuring a smooth process from selection to long-term ownership is key. This includes selecting the right supplier, understanding your warranty, and planning for minimal maintenance.

Selecting a Reputable Supplier

When you're looking for an industrial steel building, the choice of supplier is critical. We recommend partnering with companies that have a proven track record and experience in the steel building industry. Look for suppliers with over two decades of experience and a significant number of completed projects (e.g., over 4,000 projects completed). This experience translates into a deep understanding of unique business needs and the ability to deliver high-quality solutions.

A reputable supplier will offer a comprehensive project portfolio and customer service that is responsive and helpful. While we operate in Roseville and Sacramento, California, the principles of quality manufacturing, precise engineering, and reliable logistics are universal. We ensure that our building systems are designed and manufactured to the highest standards, regardless of their origin, focusing on quality control at every stage. We pride ourselves on transparent processes and firm quotes, ensuring you know exactly what to expect. A strong rating from organizations like the Better Business Bureau (BBB) also indicates a commitment to customer satisfaction.

Decoding Warranties for Your Industrial Steel Buildings

A robust warranty provides peace of mind and protects your investment. When evaluating suppliers, pay close attention to the warranty details for various components of your industrial steel building.

- Structural Warranty: This is the most crucial warranty, often spanning 50 years. It covers the integrity of the primary structural components (frames, columns, trusses) against manufacturing defects or failure under normal conditions.

- Paint Finish Warranty: Typically ranging from 20 to 40 years, this covers the exterior paint finish against issues like chalking, fading, or peeling, ensuring your building maintains its aesthetic appeal.

- Roof System Warranty: A good roof warranty, often 20-25 years for systems like Galvalume or standing seam, protects against leaks, perforations, or other failures of the roofing material.

It's important to understand the coverage details, including any exclusions or conditions (e.g., proper maintenance, installation by certified erectors). We believe in providing warranties that are second to none, reflecting our confidence in the durability and quality of our products.

Long-Term Maintenance and Upkeep

One of the most attractive benefits of industrial steel buildings is their incredibly low-maintenance nature. Unlike wood structures that require regular painting, sealing, or pest control, steel resists many common issues. This translates into significant long-term savings in both time and money.

While steel buildings are durable, a few simple practices can ensure they reach and even exceed their projected lifespan:

- Recommended Periodic Inspections: Conduct annual visual inspections to check for any minor issues, such as loose fasteners, damaged panels, or clogged gutters. Addressing small problems early prevents them from becoming larger, more costly repairs.

- Simple Cleaning Procedures: Periodically clean the exterior panels to remove dirt, grime, or environmental buildup, especially in areas with specific industrial pollutants. A simple wash can keep your building looking great for decades.

- Ensuring Maximum Lifespan: Proper drainage around the foundation, timely repair of any damage, and ensuring adequate ventilation are all straightforward steps that contribute to the longevity and performance of your steel building.

With minimal effort, your industrial steel building will continue to provide a safe, secure, and efficient space for your operations for many, many years. For specific standards on steel buildings, you can refer to organizations like the Canadian Steel Building System Standard (CSSBI) , which sets high benchmarks for quality and design.

Frequently Asked Questions about Industrial Steel Buildings

We often hear similar questions from clients considering industrial steel buildings. Here are some of the most common ones, answered to help you make an informed decision.

How long do industrial steel buildings last?

With proper construction and maintenance, a steel building can easily exceed 100 years, offering exceptional long-term value and durability. Steel is inherently robust, resisting wear and tear, pests, and fire far better than traditional materials. This longevity makes it a smart, sustainable investment that can serve your business for generations.

Do pre-engineered steel buildings need a foundation?

Yes, almost all industrial steel buildings require a precisely engineered concrete foundation to anchor the structure and support its load, typically a slab-on-grade design. The foundation is crucial for distributing the building's weight, resisting uplift forces from wind, and ensuring structural stability. While some smaller agricultural sheds might sometimes forgo a full concrete slab, for any significant industrial application, a well-designed concrete foundation is a non-negotiable component.

How can a steel building be customized for heavy equipment like cranes?

Steel buildings are ideal for crane integration. The primary framing can be engineered with reinforced columns and runway beams to support the specified crane capacity and operational loads. Our design team can incorporate specific height and clearance requirements, ensuring the safe and efficient operation of overhead cranes, hoists, or other specialized heavy equipment. This structural adaptability is a key advantage of steel, allowing your facility to be truly custom to your operational needs.

Conclusion

As we've explored, industrial steel buildings offer a compelling combination of strength, efficiency, and adaptability that makes them an ideal choice for a vast array of commercial, manufacturing, agricultural, and community applications. From their best durability and resilience against the elements to their cost-effectiveness and eco-friendly nature, steel structures truly stand out as a smart investment.

With clear-span capabilities, extensive customization options for everything from cranes to flexible layouts, and the streamlined advantages of pre-engineered construction, these buildings are designed to meet your current needs while easily accommodating future growth. We understand the unique demands of industrial operations in Roseville and Sacramento, California, and we're dedicated to delivering solutions that exceed expectations.

At Cascading Falls Inc., we pride ourselves on our commitment to quality, customer satisfaction, and best craftsmanship, embodying a "Whatever It Takes..." approach to every project. We're here to help you steer the process, ensuring your industrial steel building is not just a structure, but a high-performing asset for your business.

Ready to build smarter and stronger? Explore our comprehensive metal building services and let us help you bring your vision to life.