Why Metal Building Kits Are Changing Construction for Property Owners

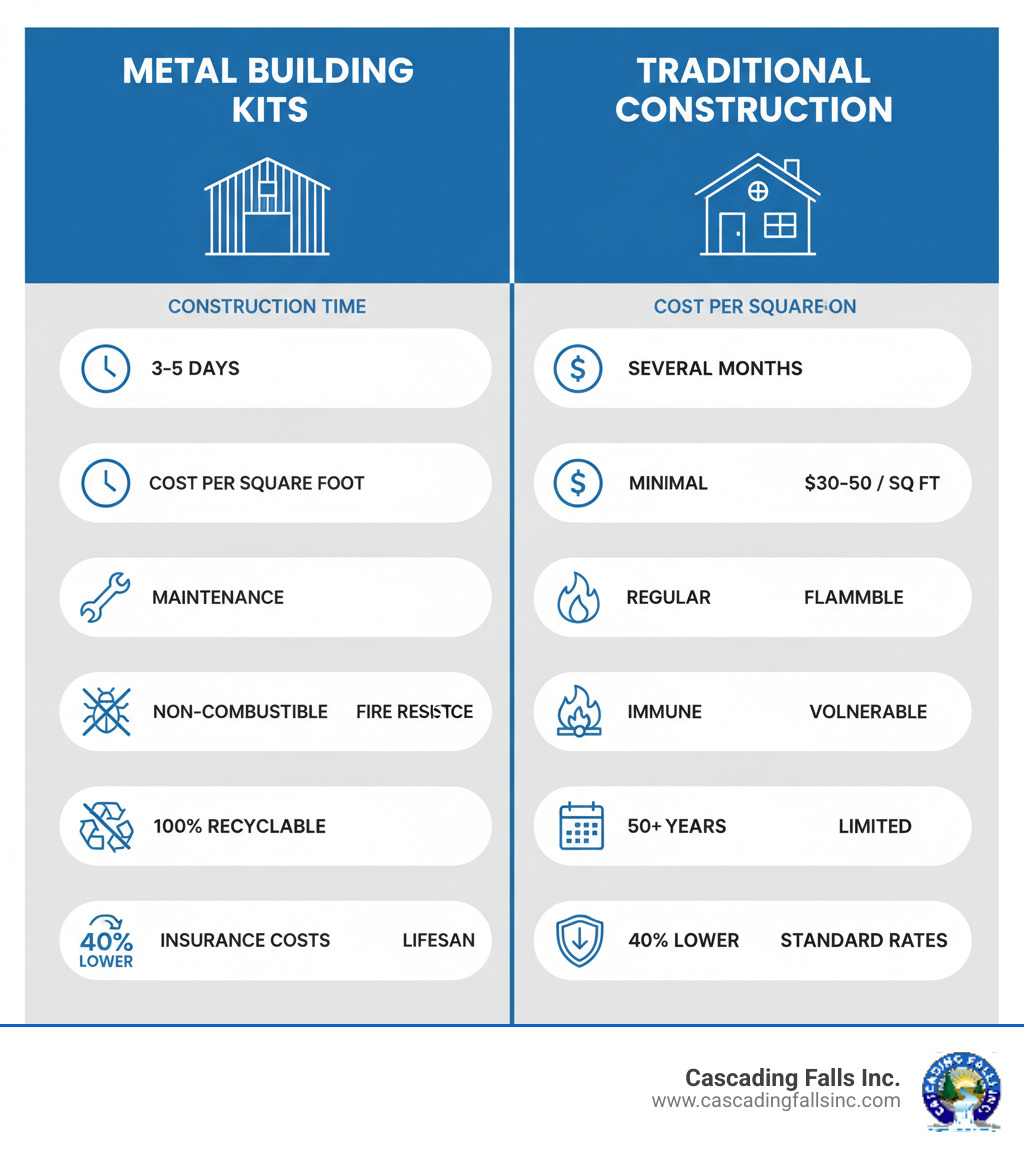

Metal building kits are pre-engineered steel structures that arrive with all primary components ready for assembly. They offer a cost-effective alternative to traditional construction, with kit prices typically ranging from $15 to $25 per square foot —representing potential savings of up to 50% compared to conventional methods.

Key Advantages of Metal Building Kits:

- Speed: Erected in as little as 3-5 days for small structures.

- Durability: Fire, pest, and mold resistant with 50-year structural warranties.

- Cost Savings: Lower insurance premiums (up to 40% less) and reduced HVAC costs.

- Versatility: Ideal for garages, barndominiums, workshops, and commercial buildings.

- Eco-Friendly: Made from up to 70% recycled steel and 100% recyclable.

- Low Maintenance: Resists rot, warping, and termite damage.

The market for prefabricated steel buildings now accounts for over 60% of new low-rise commercial construction, reflecting their superior strength, faster timelines, and design flexibility—all while meeting strict local building codes.

I'm David Shelly. With nearly two decades in construction design and project management since 2005, I've seen how metal building kits have revolutionized the industry. Through my work, I've guided many clients through selecting and installing these versatile structures.

Understanding Metal Building Kits: Types, Framing, and Components

Choosing a metal building kit involves understanding the different styles, framing, and components available.

What are the main types of metal building kits available?

When you're shopping for metal building kits, you'll encounter two main structural styles:

Arch-style buildings, often called Quonset huts , feature a distinctive semi-circular shape. These self-supporting structures are strong, budget-friendly, and excellent at handling heavy snow and wind. Their simple design makes them a great choice for DIY assembly.

Straight-wall buildings with rigid frames have a traditional rectangular shape for maximum usable interior space. They are the most versatile and customizable option, perfect for everything from barndominiums to warehouses, and they blend easily with existing properties.

Kits are available for residential uses (garages, workshops, barndominiums), commercial buildings (warehouses, auto shops, retail), and agricultural applications (horse barns, riding arenas).

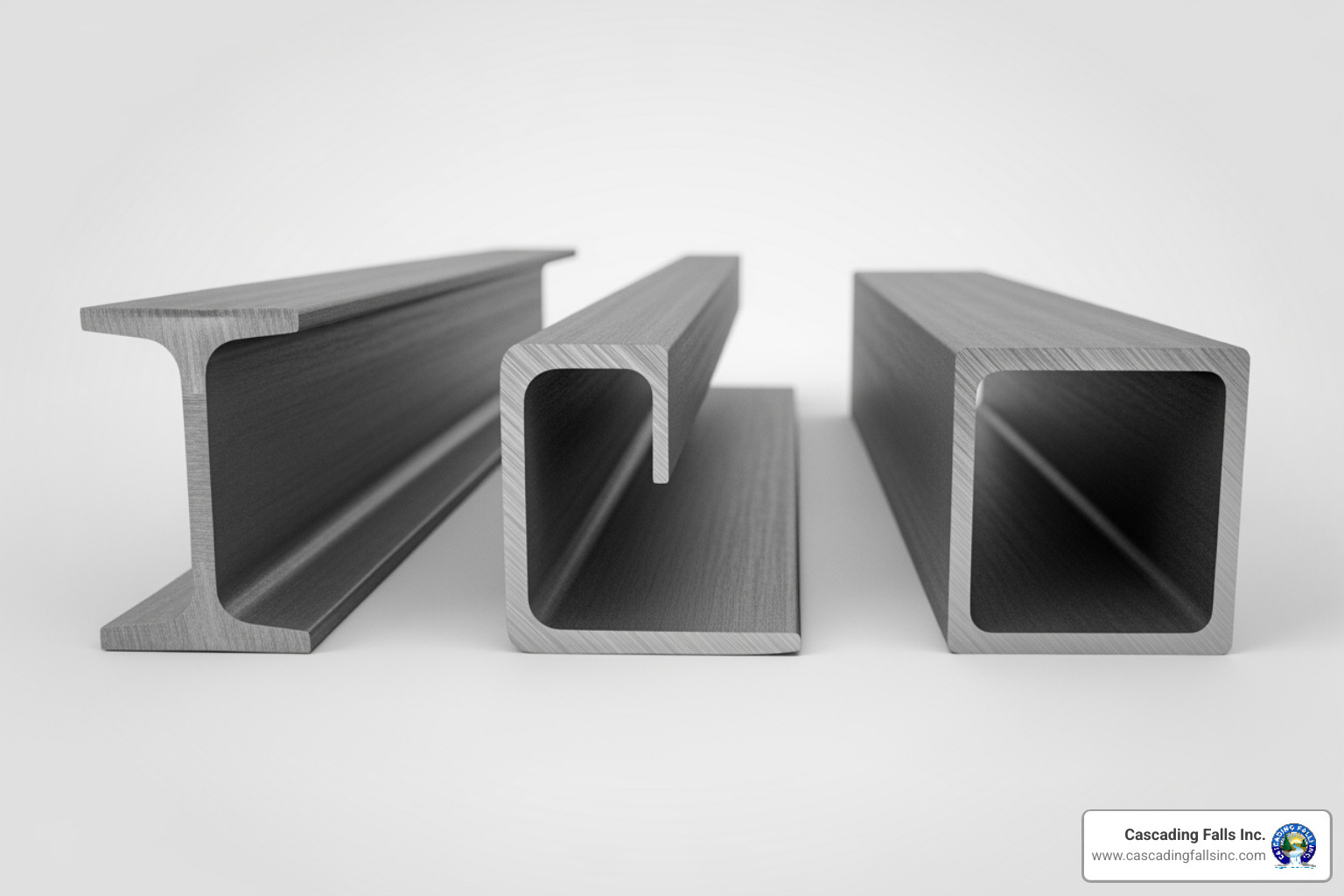

Framing Options: I-Beam, C-Channel, and Tube Steel

The frame is your building's backbone, affecting its strength, cost, and ease of assembly.

I-beam framing is the strongest option, ideal for large commercial or industrial projects. These heavy-duty steel members can create clear spans up to 300 feet wide without interior columns, which is crucial for warehouses or aircraft hangars. They are engineered to meet California's strict building codes for high winds and seismic activity.

C-channel framing is a lighter, less expensive alternative to I-beams that still provides a solid all-steel structure. It's a popular choice for medium-sized buildings, workshops, and garages where massive clear spans aren't required.

Tube framing is a budget-friendly option found in smaller DIY kits. The hollow steel tubes are easy to work with, but they are less durable and typically only handle lower wind loads. We recommend carefully checking if tube framing meets your local California building codes.

What's Typically Included in a Kit?

A metal building kit provides the complete structural shell of your building.

Standard inclusions are the primary framing (columns, rafters), secondary framing (girts, purlins), wall and roof panels, all necessary fasteners, sealants for waterproofing, trim, and engineered drawings for permits and assembly. Components are often pre-cut, pre-drilled, and numbered.

What's not included is also important to budget for. You will need to arrange for your own foundation (typically a concrete slab), labor for erection, insulation, and all interior finishing (drywall, flooring, plumbing, electrical). You are also responsible for obtaining permits.

The Steel Advantage: Why Choose a Kit Over Traditional Construction?

The surge in metal building kits represents a fundamental shift in construction, offering a powerful combination of strength, savings, and sustainability that traditional methods can't match.

Superior Durability and Safety

Steel delivers lasting safety and durability in ways wood construction cannot.

First, steel is non-combustible. It won't fuel a fire, which not only protects your investment and improves safety but can also lead to insurance premium savings of up to 40%.

Second, steel is impervious to pests. You'll never worry about termites or carpenter ants causing structural damage, eliminating the need for costly pest treatments.

Third, steel doesn't absorb moisture, making it naturally resistant to mold growth. This contributes to healthier indoor air quality and removes another maintenance headache.

Our metal building kits are pre-engineered to meet or exceed California's demanding local codes for wind and snow. They are designed to handle peak wind gusts up to 160 mph and heavy snow loads. Steel's inherent flexibility also gives it a crucial advantage during seismic events, as it can absorb and distribute energy better than rigid materials.

The quality of the steel is paramount. We work with American-made steel, often containing up to 70% recycled content. Many components feature a Galvalume® Steel coating with a 50-year warranty against rust, ensuring a durable, long-lasting structure.

Significant Cost and Time Savings

Metal building kits offer impressive savings in both time and money. All components arrive pre-engineered with pre-punched connections and numbered parts, which dramatically reduces labor hours and costs.

While traditional construction can take months, a small metal building can be erected in just a few days, and even a 10,000 square foot warehouse can be completed in weeks. This speed gets your building into use much faster.

Steel construction also minimizes waste. Compared to the 20% material waste common in lumber projects, steel generates only about 2% waste. You pay for what's in your building, not what's in the dumpster.

Long-term savings are also significant. In addition to lower insurance premiums, properly insulated steel buildings can cut heating and cooling costs by up to 60%. With no rot, warping, or termite damage, the lifetime cost of ownership is substantially lower.

Environmental and Long-Term Benefits

Steel is one of the most recycled materials on Earth. The kits we use often contain up to 70% recycled materials and are 100% recyclable at the end of their 50+ year lifespan.

Energy efficiency is another key benefit. Cool metal roofing can reflect solar heat, reducing cooling costs by up to 40% —a major advantage in California's hot summers.

The low-maintenance nature of steel saves time and money for decades. Your building remains strong and looks great with little more than an occasional wash.

Finally, manufacturer warranties provide peace of mind. These include structural warranties up to 50 years, paint warranties for 30-40 years, and roof warranties against rust for 25-50 years. These guarantees reflect the quality and longevity of the materials.

From Blueprints to Building: Applications and Customization

The versatility of metal building kits allows them to be transformed into everything from beautiful homes to busy commercial hubs.

Residential Possibilities: Barndominiums and More

Barndominiums have become incredibly popular, blending the open, airy feel of a barn with modern living comforts. They offer soaring ceilings, flexible open floor plans, and the durability of steel.

Shop houses combine living quarters with a dedicated workspace, creating a dream setup for hobbyists and small business owners.

Metal garages and personal workshops provide secure, fire-resistant spaces for vehicles, equipment, and creative pursuits. The possibilities also extend to tiny homes, RV storage, and greenhouses.

Common Commercial and Agricultural Applications

The strength and clear-span capabilities of steel make it ideal for business operations.

- Warehouses: Steel provides massive, unobstructed space for inventory and equipment, built quickly and cost-effectively.

- Auto Shops: The fire resistance and durability are crucial for mechanic garages that handle flammable materials and heavy use.

- Retail Spaces: A customizable exterior and a blank-slate interior allow for the creation of any shopping environment.

- Aircraft Hangars: Enormous clear spans accommodate large private planes while providing superior protection.

- Horse Barns & Riding Arenas: Steel offers a safe, low-maintenance environment for horses, with column-free arenas perfect for training and events.

Other applications include industrial facilities, mini-storage complexes, churches, and sports facilities.

Making It Your Own: Customization Options

A common misconception is that metal buildings are one-size-fits-all. In reality, the customization options are extensive.

- Doors and Windows: Choose from large overhead doors for equipment, glass entry doors for customers, and windows for natural light.

- Insulation: A crucial addition for comfort and energy efficiency in California's varied climate, potentially cutting energy bills by up to 60%.

- Roof Pitch and Style: Affects both aesthetics and function. A steeper pitch can create a classic look, while standing seam or cool metal roofing options add durability and reduce cooling costs.

- Colors: A wide range of color choices for walls and roofing lets you match existing structures or make a bold statement.

- Gutters and Downspouts: Essential for managing rain and protecting your foundation.

- Expandable End Walls: A smart planning choice that makes future expansion simple and cost-effective.

- Exterior Finishes: Apply brick, stucco, or faux stone siding to integrate your metal building into any neighborhood or commercial district.

Your metal building kit can be as unique as your vision. We can help guide you through these choices to create a structure that is both functional and truly yours.

Navigating the Purchase and Building Process for Metal Building Kits

Success with a metal building kit project comes from understanding the process from the start. Let's review the key considerations, from cost factors to construction.

Key Factors That Influence Cost

Several variables affect the final price of your kit.

- Building Size and Complexity: A simple 30x40 garage costs less than a 10,000 sq. ft. warehouse. Basic kits run $15-$25 per square foot for materials, but custom features will increase this.

- Steel Prices: The cost of steel fluctuates daily based on market conditions. We can sometimes help lock in pricing with flexible shipment plans.

- Geographic Location and Building Codes: Your specific location in California dictates engineering requirements for wind, snow, and seismic loads. A building engineered for high wind or snow zones will require stronger, more expensive materials.

- Custom Features: Accessories like extra doors, windows, skylights, and specialized insulation add value and cost.

- Foundation and Labor: The kit price does not include the concrete foundation (typically $5-$10 per square foot) or erection labor. It's vital to budget for the complete project.

Planning, Permits, and Site Preparation

Proper planning is essential to avoid delays and headaches.

- Foundation Requirements: Your kit needs a solid, level concrete slab with anchor bolts placed precisely according to the engineered drawings. We always recommend hiring a professional concrete company for this critical step.

- Local Building Codes: Before you buy, understand your local planning department's rules for wind, snow, and seismic resistance. Our engineered drawings are designed to meet these standards.

- The Permitting Process: Most structures over 200 square feet require a building permit. Submitting plans and getting approval can take weeks or months, so start this process early.

- Site Layout and Access: Plan your site considering property lines, drainage, and utility easements. Ensure delivery trucks and construction equipment have clear access. You'll also need a level area to store kit components.

- Utility Hookups: If you need electricity, plumbing, or HVAC, plan for these connections during the site preparation phase.

DIY vs. Professional Installation: What to Consider

This is the big question we hear constantly: "Can I build this myself?" The answer depends on your budget, time, and skill.

DIY installation can save you thousands in labor costs. Small structures under 2,000 square feet can be erected in a few days by a small team with basic construction knowledge. Kits are designed to be DIY-friendly, with pre-punched and numbered components. If you can read blueprints and handle power tools, a straightforward build is achievable.

However, larger or more complex buildings benefit from professional installation. For commercial structures or projects with a tight deadline, hiring experts ensures the job is done quickly and correctly.

Both approaches can be successful. We provide guidance for DIY builders and can connect you with qualified contractors in the Sacramento and Roseville areas for professional installation. Choose the path that best fits your skills, timeline, and budget.

Frequently Asked Questions about Metal Buildings

We love talking with property owners about metal building kits, and over the years, we've noticed certain questions come up again and again. Let's tackle some of the most common ones.

How long does it typically take to erect a metal building kit?

One of the biggest advantages of metal building kits is their rapid assembly time. Because components are pre-engineered, the timeline is significantly shorter than traditional construction.

- A small structure (under 2,000 sq. ft.) can typically be erected by a small team in just 3 to 5 days.

- A medium-sized building (around 5,000 sq. ft.) can be assembled in about a week.

- Even large warehouses (10,000 sq. ft.) are often completed in a matter of weeks, not months.

This speed translates directly into labor cost savings and allows you to use your new building much sooner.

What kind of warranties are typically offered on the structure and paint?

When you invest in a metal building kit, you're buying decades of protection. The warranties that come with these structures reflect the confidence manufacturers have in their products.

- Structural Warranties: Typically cover the primary steel frame for 25 to 50 years against structural defects.

- Roof Warranties: Standard Galvalume® steel roofs often come with a 25 to 50-year warranty against rust perforations.

- Paint Warranties: The finish on wall and roof panels is usually covered for 30 to 40 years against chipping, peeling, and fading.

These warranties represent real peace of mind that your investment is protected for the long term.

Are metal buildings suitable for all climates?

Yes, high-quality metal building kits are suitable for any climate when properly engineered. While some light-duty kits are only for mild weather, robust I-beam structures are designed for extreme conditions.

Here in California, we engineer buildings for our diverse climate, from Sacramento's summer heat to the Sierra's heavy snow. Your kit's engineered drawings will be customized to meet or exceed local codes for:

- Wind Loads: Often designed for gusts up to 160 mph.

- Snow Loads: Engineered to handle heavy snowfall in mountain regions.

- Seismic Events: Steel's flexibility allows it to perform exceptionally well during earthquakes.

With the right insulation package, your metal building will remain comfortable and energy-efficient in any weather.

Conclusion

We've explored how metal building kits have become a game-changer for property owners seeking a better alternative to traditional construction.

These kits offer remarkable versatility for any project, from a barndominium to a commercial warehouse. They deliver exceptional durability against fire, pests, and California's demanding weather, all while being genuinely cost-effective. You save money upfront, on insurance, on energy bills, and through minimal maintenance.

Whether you're a DIY enthusiast or prefer professional installation, a metal building kit puts you in control of your project. It's a smart investment backed by warranties that can last for fifty years.

At Cascading Falls Inc., our "Whatever It Takes..." philosophy means we're committed to quality and customer satisfaction. We're with you every step of the way, from initial planning to the final walkthrough.

If you're ready to start your metal building kit project, we're here to help turn your vision into reality. Explore our comprehensive metal building services and let's discuss your project.