Why Choosing the Right Concrete Steps Company Matters

Concrete steps are a fundamental element of your property's curb appeal, safety, and value. Choosing the right concrete steps company is crucial, as quality installation with high-strength, steel-reinforced concrete can result in steps that last 50+ years. Poor construction, on the other hand, can lead to cracks, water damage, and safety hazards. When selecting a provider, focus on these key criteria:

Key Selection Criteria:

- Experience & Specialization- Look for 10+ years in concrete work with a proven portfolio.

- Quality Materials- High-strength, steel-reinforced concrete that meets building codes.

- Installation Process- Proper site prep, reinforcement, and curing techniques.

- Customization Options- Width, color, finish styles (stamped, broom, exposed aggregate).

- Clear Communication- Free estimates, transparent pricing, and warranty information.

The right company understands the technical details that ensure longevity. This includes using wet cast, air-entrained concrete for durability in freeze-thaw cycles and constructing deep footings (e.g., 4 feet in cold climates like Minnesota) to prevent frost heave. They adhere to residential building codes, such as 7-inch risers and 12-inch treads, for maximum safety. They also offer a range of options, from precast to poured-in-place solutions, to fit your landscape perfectly.

I'm David Shelly, and with nearly two decades of experience in landscape construction, I've helped countless property owners select the right concrete steps company. This guide will give you the information you need to make a confident, informed decision.

Understanding Your Options: Types and Styles of Concrete Steps

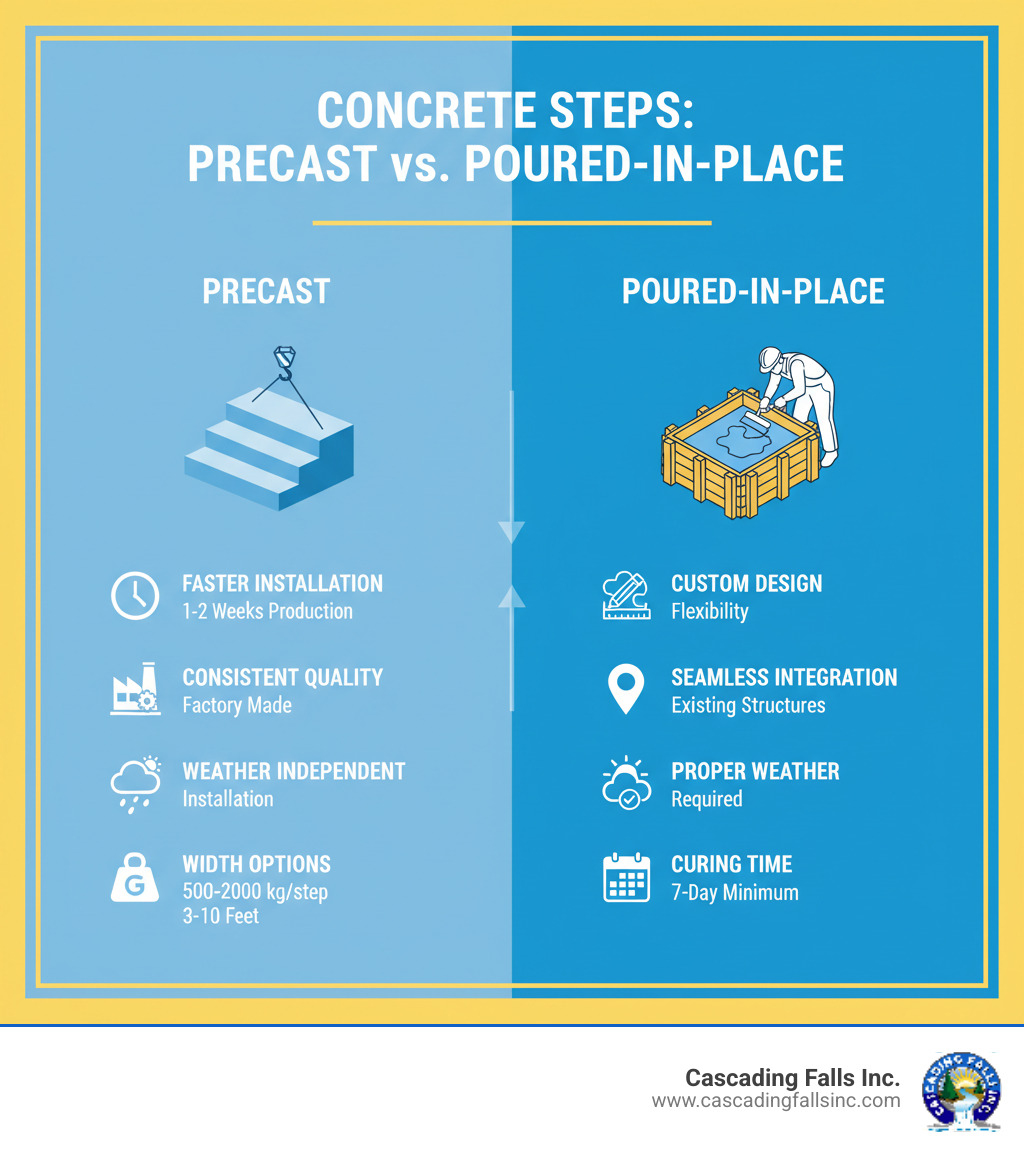

Planning a concrete steps project involves choosing between two main types: precast and poured-in-place. This decision impacts your timeline, budget, and final look. A skilled concrete steps company will guide you to the best option for your needs, balancing function and beauty.

Precast concrete steps are manufactured in a factory and delivered ready for a quick installation. Made with high-strength, steel-reinforced concrete, they offer consistent quality and are not subject to weather delays during production. Precast steps are available in standard widths from 3 to 10 feet, with various landing depths. Some manufacturers even offer lightweight versions for easier transport.

Poured-in-place steps are built on-site, offering complete customization. This method is ideal for unique designs, such as curved steps or seamless integration with existing walls. While the process takes longer and depends on good weather, it provides unparalleled flexibility for complex or unusual spaces.

You'll also choose between monolithic and modular designs. Monolithic steps are cast as a single, exceptionally strong unit. Modular designs allow for larger custom applications beyond standard widths, perfect for grand entrances.

Precast vs. Poured-in-Place: Which is Right for You?

This table breaks down the key differences:

| Feature | Precast Concrete Steps | Poured-in-Place Concrete Steps |

|---|---|---|

| Speed | Faster installation (production 1-2 weeks, quick on-site install) | Slower installation (requires on-site forming, pouring, and curing) |

| Consistency | Factory-manufactured for uniform quality and strength | Quality can vary depending on on-site conditions and crew expertise |

| Weather Independence | Manufacturing is weather-independent; installation less weather-sensitive | Requires suitable weather conditions for pouring and initial curing |

| Customization | Standardized sizes and designs, limited on-site modification | Highly customizable for unique shapes, sizes, and integration |

| Seamless Integration | Can be designed to fit, but less seamless than poured | Excellent for seamless integration with existing structures |

| Site Adaptability | Requires level, prepared base; less adaptable to uneven terrain | Highly adaptable to challenging or uneven site conditions |

Aesthetics and Customization

Modern concrete steps offer a vast range of aesthetic choices:

- Color options: Integrated colors are mixed directly into the concrete for rich, fade-resistant hues that won't chip or peel.

- Stamped concrete patterns: Replicate the look of natural flagstone, slate, brick, or even wood grain at a fraction of the cost.

- Finishes: A classic broom finish provides excellent slip resistance, while an exposed aggregate finish reveals the stones within the concrete for a textured, high-end look.

- Configuration: Steps can be customized for width, landings, and riser/tread dimensions. Standard residential codes call for 7-inch risers and 12-inch treads for comfort and safety.

- Handrail integration: Maintenance-free aluminum handrails are a popular choice, providing safety without compromising design. They can be integrated with new stairs, patios, and landings.

Concrete steps can be part of a larger project, including patios, walkways, and driveways. You can find more info about concrete services to see how these elements can work together.

The Blueprint for Quality: Construction Standards and Materials

The longevity of your concrete steps depends on the quality of materials and construction. A reputable concrete steps company uses high-strength, steel-reinforced concrete and follows strict standards to ensure your investment lasts for decades. At Cascading Falls Inc., we believe quality isn't negotiable.

Key materials include high-strength concrete and steel rebar reinforcement, which together create a structure that resists cracking. Some precast options use lightweight concrete formulations that reduce weight without sacrificing durability. Proper footings are essential everywhere to prevent settling and shifting; while Minnesota may require 4-foot depths to prevent frost heave, we assess California soil conditions to determine the appropriate depth for stability.

We adhere strictly to building codes, including the standard 7-inch riser height and 12-inch tread depth, which ensures safe and comfortable use.

The Installation Process Explained

A professional concrete steps company follows a precise installation sequence. Here’s a summary of our process:

- Site Preparation: We clear the area, handle demolition of old steps, obtain necessary permits, and compact the base to create a stable foundation.

- Formwork Construction: We build sturdy forms from plywood and lumber, ensuring they are plumb, level, and correctly pitched for water drainage. For a look at the craftsmanship involved, see A guide to building concrete steps.

- Pouring and Placement: We install a grid of steel rebar for reinforcement before pouring the concrete. We carefully work the concrete to eliminate air pockets and then screed, float, and edge the surface. A broom finish is applied for slip resistance.

- Curing and Protection: We apply an acrylic cure and seal product to slow the drying process, which is crucial for the concrete to reach its full strength. The area is barricaded to protect the steps as they cure for several days.

- Sealing: A final seal provides an extra layer of protection against moisture, staining, and wear, extending the life and appearance of your steps.

Quality Control and Safety on the Job

Our "Whatever It Takes..." philosophy means we never cut corners. We implement rigorous quality control, including mix design verification, rebar inspection, and formwork integrity checks. We use effective curing methods and perform slump tests to ensure concrete consistency, following standards outlined in resources like Essential concrete works checklists.

Safety is paramount. Our crew uses proper personal protective equipment (PPE), and we establish clear barricades around work zones. All equipment is regularly inspected, and we conduct daily toolbox talks to review safety protocols. This commitment to excellence ensures your project is executed flawlessly and safely.

How to Vet a Concrete Steps Company for Your Project

Choosing the right concrete steps company is a long-term investment in your property. To find a reliable partner, you need to vet them carefully. Here’s what to look for to avoid future problems.

First, review their portfolio of completed projects. This shows their capabilities and if their style matches your vision. Look for clean edges and professional finishes. Next, read customer testimonials to get honest feedback on their communication, timeliness, and professionalism. Finally, always verify that the company has proper licensing and insurance, including liability and workers' compensation. This is your protection in case of accidents or property damage.

Pay attention to communication from the start. A professional company should listen to your goals and provide a detailed estimate that breaks down all costs and services. If they are evasive or hard to reach during the vetting process, it's a red flag.

Evaluating the Experience of a Concrete Steps Company

Experience is essential in concrete work. Look for a concrete steps company with a proven track record.

- Years in business: A company with a decade or more of experience has demonstrated consistency and reliability.

- Specialization: A specialist in concrete work will have a deeper understanding of materials, techniques, and local building codes than a generalist.

- Project types: Experience with both residential and commercial projects shows they can manage jobs of varying complexity and scale.

- Local climate experience: A local company, like Cascading Falls Inc. in Roseville and Sacramento, understands how California's climate affects concrete curing and material selection.

- Project gallery: Photos provide clear evidence of their craftsmanship and the range of styles they can produce.

What to Expect from a Professional Concrete Steps Company

Working with a professional concrete steps company like Cascading Falls Inc. should be a straightforward and transparent process. Our "Whatever It Takes..." approach ensures a smooth experience.

- Free, no-obligation estimates: We assess your property and provide a detailed estimate, typically within one to two days.

- Detailed project scope: The estimate will clearly outline all aspects of the project, including materials, dimensions, finishes, and timelines.

- Transparent pricing: We provide itemized pricing with no hidden fees. Any changes are discussed and approved by you first.

- Warranty information: We stand behind our work with clear warranties on materials and workmanship for your peace of mind.

- Professionalism and workmanship: Our team is punctual, respectful of your property, and maintains a clean job site.

You can learn more about our full range of services and see examples of our work at our concrete services page.

Long-Term Care: Maintaining Your Concrete Steps for Decades

With simple, regular maintenance, your quality concrete steps can last for 50 years or more. A professional concrete steps company should provide you with care instructions, but here are the key practices to protect your investment.

-

Regular Cleaning: Sweep your steps weekly to remove debris that traps moisture. For a deeper clean, use a garden hose, a soft-bristled brush, and mild soap. Avoid pressure washers, which can damage the surface.

-

Avoid Harsh Deicers: While not a major concern in Roseville and Sacramento, it's good to know that deicers containing ammonium nitrates or sulfates can damage concrete. Sand is the safest option for traction on any icy surface.

-

Annual Sealing: This is the most important maintenance task. Applying a penetrating sealer once a year creates a protective barrier against moisture and stains. We recommend an acrylic cure and seal product, which also improves the concrete's strength.

-

Inspect and Repair: Regularly check for small hairline cracks or chips, especially after heavy rains. These can often be patched with concrete repair products from a hardware store. For more significant issues like settling or large cracks, call a professional concrete steps company for an assessment. Addressing minor problems early can prevent costly replacements later.

Frequently Asked Questions about Concrete Steps

Here are answers to some of the most common questions homeowners have about concrete steps.

How long do concrete steps last?

With proper installation and basic maintenance, high-quality concrete steps can easily last 50 years or more. Their longevity is due to the inherent durability of steel-reinforced concrete and its excellent weather resistance. They are unaffected by insects, rot, or precipitation. The key is a professional installation by a skilled concrete steps company and simple annual care, like cleaning and sealing.

Can concrete steps be repaired?

Yes, in many cases, repair is a cost-effective alternative to full replacement. A professional concrete steps company can assess the damage and recommend the best solution.

- Crack Repair: Small cracks can be filled and sealed to prevent water intrusion and further damage.

- Resurfacing: If the steps are structurally sound but the surface is worn, a concrete overlay can provide a fresh, new look.

- Leveling: Sunken or uneven steps can often be lifted and stabilized through a process called mudjacking or slabjacking, eliminating trip hazards.

Replacement is typically only necessary for severe structural damage or widespread deterioration. A professional assessment will determine the most sensible long-term solution for your budget and property.

What applications are best for concrete steps?

The versatility of concrete steps makes them suitable for a wide range of applications:

- Residential Entryways: They boost curb appeal and provide safe, durable access that can be customized to any architectural style.

- Commercial Buildings: Concrete is ideal for handling heavy foot traffic while meeting accessibility standards and requiring minimal maintenance.

- Industrial Access: They provide safe and durable access to platforms and equipment in demanding industrial environments.

- Patios and Decks: Steps create a seamless transition from outdoor living spaces to the yard, integrating beautifully with other hardscape elements.

- Landscape Integration: Use them to create pathways through gardens or manage elevation changes on sloped properties, blending function with design.

In Roseville, Sacramento, and beyond, concrete steps offer a solution that is both built to last and designed to impress.

Conclusion

Your home's entrance sets the first impression. Choosing the right concrete steps company is an investment in quality craftsmanship that improves your property's value and appeal for decades. This guide has highlighted the importance of understanding your options, from fast precast steps to fully custom poured-in-place designs, and the variety of aesthetic finishes available.

We've emphasized that quality is rooted in technical excellence: high-strength, steel-reinforced concrete, proper footings, and a meticulous installation process from site prep to final sealing. Vetting a company based on their experience, portfolio, and transparent practices ensures you partner with a true professional. With simple annual maintenance, your investment will provide safe, attractive access for 50 years or more.

At Cascading Falls Inc., our "Whatever It Takes..." philosophy means we are committed to exceeding your expectations. Serving Roseville, Sacramento, and surrounding California communities, we bring nearly two decades of experience to every project. We understand our local climate and building codes, and we care about creating solutions that improve your property's beauty and safety.

Whether you need durable precast steps or a custom-poured entrance, we are here to bring your vision to life.

Ready to get started? Contact us for your concrete project today for a free, no-obligation estimate. Let's create something beautiful that will welcome you home for decades to come.