What is Prefabricated Metal Construction?

Prefab metal building construction is revolutionizing how we build. Instead of constructing piece by piece on-site, prefabricated metal buildings are engineered in controlled factory environments, then shipped as complete kits for quick assembly.

The prefab metal building construction process includes:

- Off-site manufacturing in specialized facilities

- Pre-drilled components that arrive ready to bolt together

- On-site assembly in days, not months

- Quality control for precision and consistency

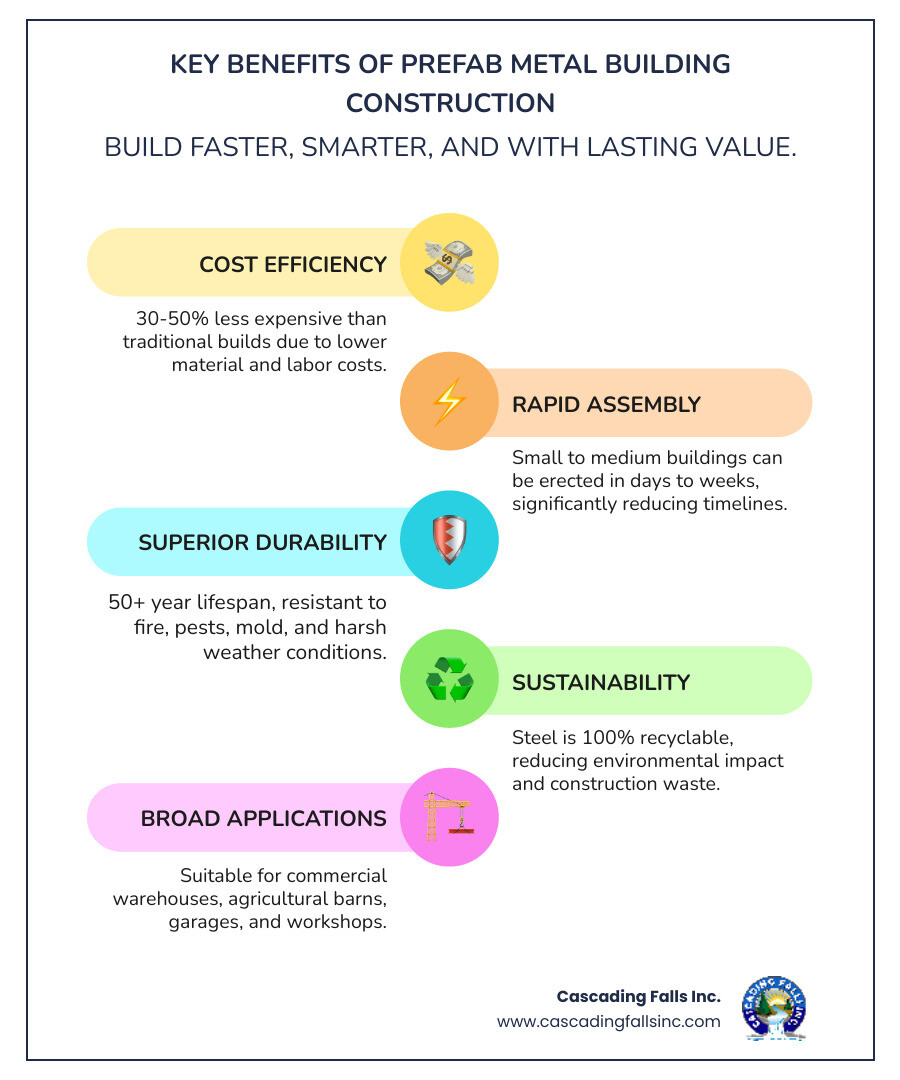

- Cost savings of 30-50% over traditional construction

This method has gained massive popularity because it delivers faster timelines, lower costs, and superior durability. Steel is the primary material due to its strength, spanning capabilities, and resistance to fire, pests, and weather.

With nearly two decades in construction and project management, I've seen how prefab metal building construction transforms project timelines and budgets. This experience provides unique insight into what makes these systems so effective for both residential and commercial applications.

Why Choose a Prefab Metal Building?

When planning your next project, smart builders and business owners are choosing prefab metal building construction for several key reasons.

First, the cost. Prefab metal building construction typically costs 30-50% less than traditional wood or concrete. These savings come from an efficient factory process with less waste and no weather delays.

Second, the speed. While a traditional building can take months, your prefab structure can be ready in days or weeks. Pre-cut, pre-drilled components make assembly lightning fast.

Third, design flexibility. Modern prefab buildings are highly customizable. Steel's strength allows for clear-span interiors without support columns, and you can specify the exact windows, doors, and colors you want.

Fourth, durability. Steel resists termites, storms, and fire. These structures can last 50+ years with minimal maintenance—no rotting, warping, or constant repainting.

Finally, sustainability. Steel is one of the most recycled materials on Earth, and the factory process creates far less waste than traditional construction sites.

Key Benefits of Prefab Metal Building Construction

- Reduced labor costs: Most work is done in the factory, lowering on-site hours and expenses.

- Minimal construction waste: Factory precision means materials are used efficiently, not sent to a dumpster.

- Clear-span interiors: Get up to 100 feet of unobstructed space, perfect for warehouses, workshops, and industrial use.

- Resistance to fire, pests, and mold: Steel doesn't burn, pests can't eat it, and it won't grow mold, leading to a healthier building and lower insurance costs.

- Recyclable materials: At the end of its long life, the entire steel structure can be recycled into new products.

- Predictable project schedule: Indoor manufacturing eliminates weather delays, so your timeline is reliable.

Common Applications for Steel Buildings

The versatility of prefab metal building construction makes it suitable for nearly any application.

- Commercial warehouses and industrial facilities benefit from the open floor plans and strength.

- Agricultural barns and equipment storage buildings stand up to weather while keeping maintenance low.

- Residential garages and workshops offer durability and design options that outlast traditional structures.

- Retail spaces can be customized for a professional appearance and efficient layout.

From airplane hangars to sports complexes, steel construction delivers better value, faster completion, and longer-lasting results. At Cascading Falls Inc., we uphold our "Whatever It Takes" commitment to getting every project right.

The Step-by-Step Prefab Metal Building Construction Process

The prefab metal building construction process is straightforward and predictable, breaking down into three main phases: design, site preparation, and assembly. This clear roadmap avoids the delays and surprises common in traditional construction, getting you into your new building faster.

Phase 1: Design, Engineering, and Permitting

This phase starts with a concept discussion to understand your vision. We then create a custom design that fits your specific needs, whether it's extra-wide doors or specific insulation. Next, your building is custom-engineered to meet all local building codes, accounting for challenges like heavy snow or high winds. Once complete, you'll receive stamped blueprints essential for the permit application process. These permits protect you by ensuring your building is safe and legal.

Phase 2: Site Preparation and Foundation

With permits approved, we prepare your site. This involves land clearing and grading to create a level base and ensuring utility access for electricity and water. The foundation is critical, and most projects use concrete for its stability. As experts in concrete work, we know that pouring the foundation and ensuring perfect anchor bolt placement are essential for a smooth assembly. We'll recommend the right foundation type for your building's size, use, and local soil conditions.

Phase 3: Delivery and Assembly

This is the fastest phase, where your building takes shape in days. Your custom-fabricated components arrive on-site as a complete kit. All pre-drilled parts and pre-cut panels fit together exactly as engineered, with no on-site cutting or drilling. The process involves bolting the frame together, hoisting sections into place, and attaching wall and roof panels. While many kits are designed for DIY assembly, professional erector services are available through Cascading Falls Inc. Our experienced crews ensure an efficient and safe assembly, often completing the job faster than you might expect.

Customizing Your Steel Structure: From Blueprint to Reality

One of the biggest myths about prefab metal building construction is that you're limited to a boring box. The truth is, steel's strength opens up a world of customization. We've helped clients create everything from sleek modern offices to rustic barns and stunning barndominiums. The steel structure is a strong, reliable canvas for your vision, allowing for massive clear spans and precise placement of doors and windows without compromising strength.

Choosing Your Building Style and Features

Your design starts with a basic building style. Rigid frame buildings are the workhorses, offering a traditional look with incredible clear-span capabilities, perfect for warehouses or large garages. Quonset huts, with their distinctive arch shape, are highly efficient, budget-friendly, and quick to assemble. Other arch and straight-wall styles offer different combinations of aesthetics and function.

Once you've chosen a structure, you can customize it further:

- Roof profiles: A gable roof offers a traditional look, while a single slope roof creates a modern aesthetic. Monitor roofs add height and natural light.

- Doors: Choose from functional roll-up doors, garage-style overhead doors, standard walk-in doors, or space-saving sliding doors.

- Windows and Vents: Add windows and skylights for natural light, reducing energy costs. Vents ensure proper airflow and air quality.

Many suppliers offer online design tools to help you visualize different layouts, colors, and features.

Factors Influencing Your Prefab Metal Building Construction Cost

While prefab is affordable, several factors influence the final cost. Understanding them helps you budget effectively.

- Building size: This is the primary cost driver, with kits typically ranging from $10-$25 per square foot.

- Steel thickness: Standard 29-gauge panels are common, but upgrading to thicker 26-gauge steel adds durability. Framing is typically 14-gauge or heavier 12-gauge steel.

- Customization complexity: Each door, window, or special feature adds to the price but improves functionality. Insulation packages start around $2-$4 per square foot.

- Foundation requirements: A simple concrete slab might add $4-$8 per square foot, but complex foundations cost more.

- Shipping and Labor: Shipping costs vary by distance. Local labor rates for professional erection typically run $3-$10 per square foot, though DIY assembly is an option.

At Cascading Falls Inc., we believe in transparent pricing with no hidden fees.

Durability, Lifespan, and Sustainability of Metal Buildings

When investing in a building, you want it to last. This is where prefab metal building construction truly excels. Unlike wood that can rot, warp, or be eaten by termites, steel stands firm against moisture, pests, and temperature swings. This inherent toughness translates directly into lower maintenance costs and greater peace of mind.

How Long Do Metal Buildings Last?

A properly constructed steel building can easily last 50 years or more, a fact backed by solid warranties. Many manufacturers offer 50-year structural warranties and long-term warranties on paint and roofing, reflecting confidence in the product's longevity.

The secret is the steel itself. Modern construction uses galvanized steel and advanced coatings that create a protective barrier against rust and corrosion. This protection is vital in coastal areas or regions with harsh winters.

Steel's natural advantages set it apart: fire won't consume it, termites won't eat it, and mold won't grow on it. This resistance minimizes repair bills and maintenance, which is often as simple as an occasional wash-down. This hands-off approach saves you time and money over the building's lifetime.

The Eco-Friendly Choice

Building responsibly is essential, and prefab metal building construction is one of the most environmentally conscious choices available.

Steel has an incredible environmental story. It contains a high percentage of recycled content from the start, reducing the need for new raw materials. Even more impressively, steel is 100% recyclable at the end of its life. When a steel building is retired, every component can be recycled into new steel products without any loss of quality.

The construction process is also cleaner. Factory prefabrication minimizes waste, as most cutting and shaping happen in a controlled environment where scrap is easily recycled. Paired with modern insulation and reflective roof coatings, steel buildings can also be highly energy-efficient, lowering heating and cooling costs.

From its recycled content to its complete recyclability, prefab metal building construction represents a remarkably sustainable approach to building.

Frequently Asked Questions about Prefab Metal Buildings

Here are answers to the most common questions we receive about prefab metal building construction projects.

How much cheaper are prefab metal buildings than traditional construction?

You can expect savings of 30-50% compared to conventional wood or concrete structures. These savings come from multiple efficiencies: minimal material waste from factory production, significantly lower labor costs due to faster assembly, and shorter construction timelines that let you use your building sooner.

I've seen clients who were initially skeptical become believers when they see the final numbers. One recent warehouse project saved our client over $40,000 compared to a traditional concrete building quote they'd received.

How long does it take to construct a prefab metal building?

The speed is remarkable. Small to medium-sized buildings often go up in just days to a few weeks —a timeline that would be months for traditional methods.

For larger, more complex industrial projects, you're looking at a few months from foundation to completion, which is still significantly faster than conventional construction. The secret is the pre-cut and pre-drilled components that make assembly incredibly efficient and predictable.

Do I need a permit for a prefab metal building?

Yes, in almost every case, you will need a building permit. This is a necessary step to ensure your building is safe and compliant with local regulations.

The process involves submitting professionally engineered plans that meet all local building codes, accounting for your area's specific wind loads, snow loads, and seismic requirements. This thorough engineering is a hallmark of prefab construction and is appreciated by most building officials, often making the approval process smoother.

I always recommend contacting your local building department early in the planning process to understand any specific requirements for your area.

Conclusion: Build Faster, Stronger, and Smarter

Prefab metal building construction is a game-changer, delivering dramatic cost savings of 30-50%, construction times measured in days or weeks, and durability that lasts 50+ years with minimal maintenance.

The versatility of steel means your vision can become a reality, whether you're planning a sprawling commercial warehouse, a cozy backyard workshop, a resilient agricultural barn, or a unique barndominium. The clear-span capabilities and design flexibility ensure your specific needs are met.

Choosing prefab metal building construction is a smart investment. The combination of low upfront costs, minimal maintenance, energy efficiency potential, and complete recyclability creates a solution that makes sense both financially and environmentally. You're not just buying a building; you're investing in decades of reliable service.

This construction method eliminates common project headaches. The predictable schedule and controlled costs mean you can plan with confidence, free from worries about weather delays or surprise overruns.

For a seamless project from foundation to finish, Cascading Falls Inc. brings best craftsmanship and a "Whatever It Takes" commitment to your build. We understand your project is your vision, and we're here to guide you through every step with the precision and quality you deserve.

Ready to build faster, stronger, and smarter? Explore our comprehensive building Services to get started on your next project with us. Your perfect metal building is just a conversation away.